Major works at the Tuvatu gold mine include mill site bulk earthworks such as excavation and fill capabilities for mine ore stockpile, a processing plant, a maintenance building, a crushing plantĪ 7MWp sun2live solar/ diesel hybrid power plant is planned to be constructed 3.5km from the project. Construction and infrastructure facilities at Tuvatu gold mine Gold will be recovered through elution of carbon and electro-winning.

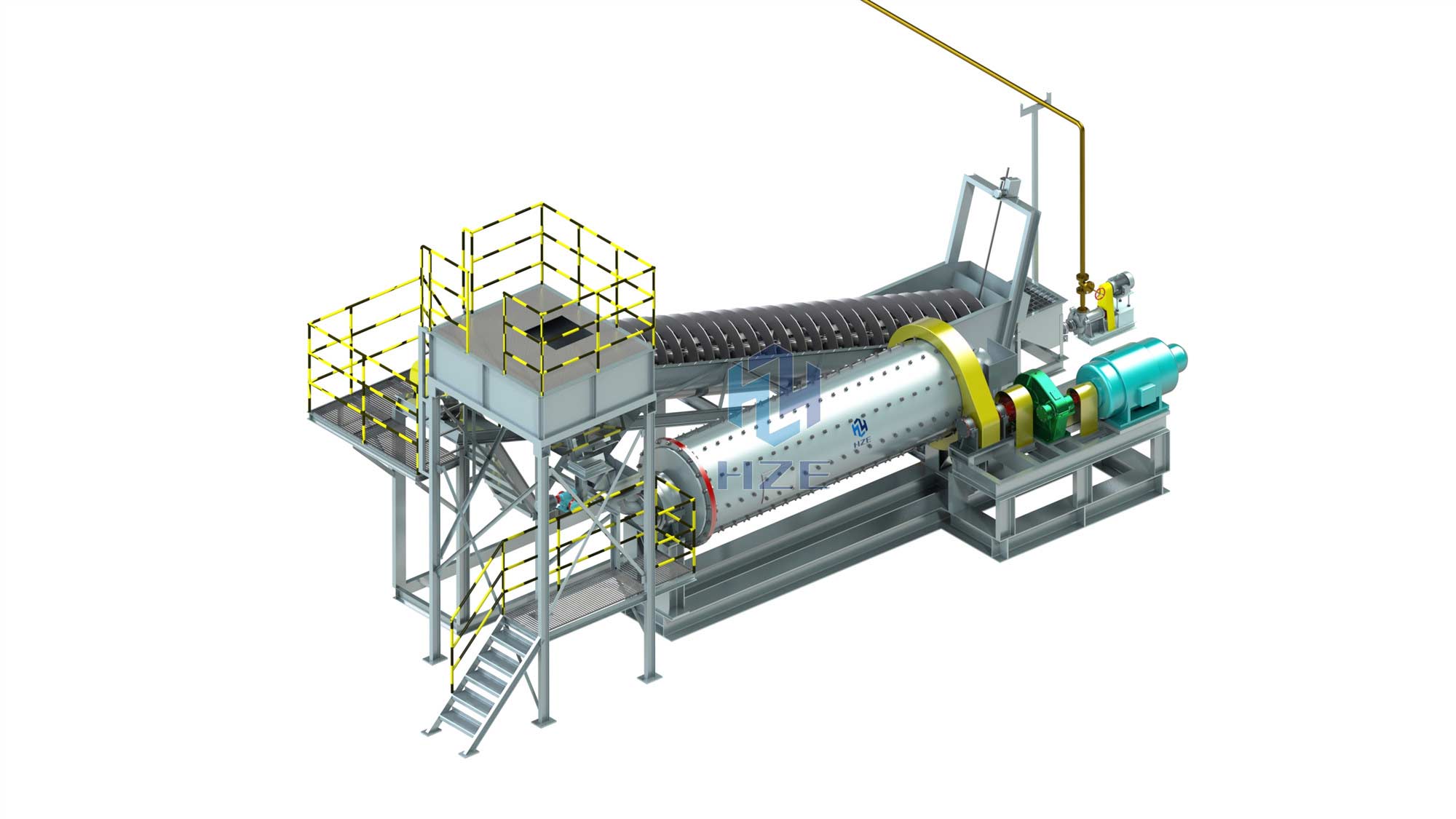

The tailings from the processing plant will be conveyed to the tailings storage facility. The output of the grinding circuit will be thickened and treated in a carbon-in-leach (CIL) circuit to extract and absorb solution gold onto carbon particles. The reclaimed ore will be processed through a grinding circuit consisting of a primary ball mill, a secondary ball mill, and gravity circuit. The crushed material will be carried by conveyors to a reclaim stockpile with a 600t live capacity. Ore processing facilities include a primary crusher coupled with a secondary crusher that operates at a capacity of 1,000t/d. The processing plant has a capacity of 219,000t/y with a 600t/d feed.

#Gravity circuit gold mining manual

Mining at the Tuvatu mine will be carried out using the manual shrinkage stoping method for steep-dipping lodes and breast mining method for flat-dipping lodes. Inferred resources are estimated to be 1.506Mt grading at 9.67g/t and containing 468,000oz of gold at a cut-off grade of 3g/t. The Tuvatu gold project is estimated to contain indicated resources of 1.101Mt of ore grading 8.46g/t and containing 299,500oz of gold. It also hosts porphyry copper-gold and volcanic-hosted massive sulphide (VMS) type mineralisation. The Tuvatu deposit is a low-sulphidation epithermal gold-vein deposit situated along an eroded Navilawa volcanic centre. The Fijian Islands are located along the margins of the south-west Pacific Rim oceanic tectonic plate, which hosts epithermal gold-silver and porphyry copper-gold deposits such as Porgera, Misima, Ok Tedi, Lihir, and Bougainville. It lies within the Viti Levu Lineament in Fijian Islands with a northeast-southwest lineament accompanied by several alkaline volcanic centres. The Tuvatu underground gold mine is spread over 5ha within a 385ha mining lease. Tuvatu gold mine geology and mineralisation Non-Metallic Mineral Mining and Quarrying.As technology improved and provincial and federal governments started monitoring the environmental impact of mining, many of the area's mills introduced autoclaves. Campbell Red Lake Mines used roasters to breakdown their arsenopyrite-rich ore, while other mines in the district lacking this geological feature used different technology. For example, some mills used a ball mill, while others used a pebble mill. Each mine customizes the mill equipment according to what will work best with the geology of their deposit.

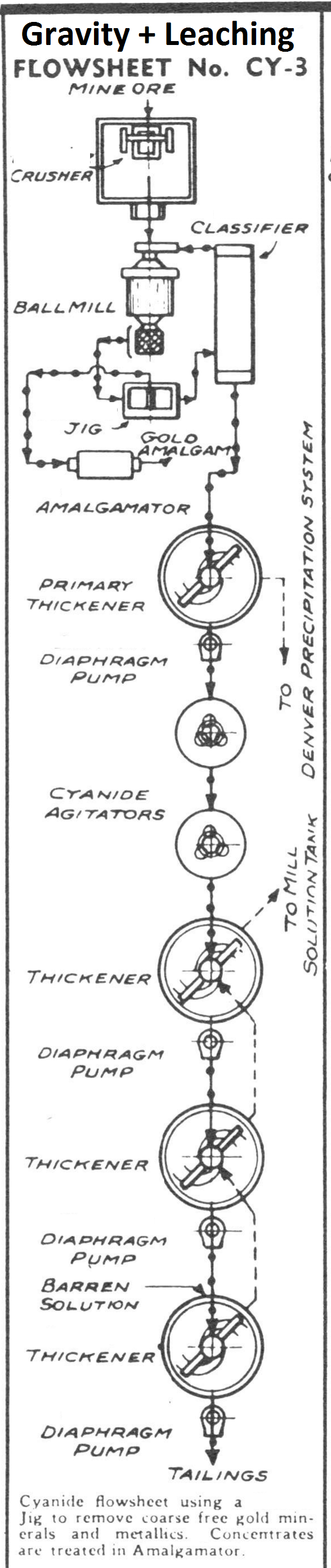

While the main steps for extracting gold are the same, but the equipment used can vary from mine to mine. Today, most gold mining mills use a combination of gravity circuits and concentration leaching to separate gold from the ore. These processes are more efficient and require less regulation for worker safety.

Historically, mines would use amalgamation (with mercury), but technological advances have now replaced this process. Extracting gold can be done through amalgamation, gravity concentration or leaching. The mineral extraction process varies depending on the mineral.

0 kommentar(er)

0 kommentar(er)